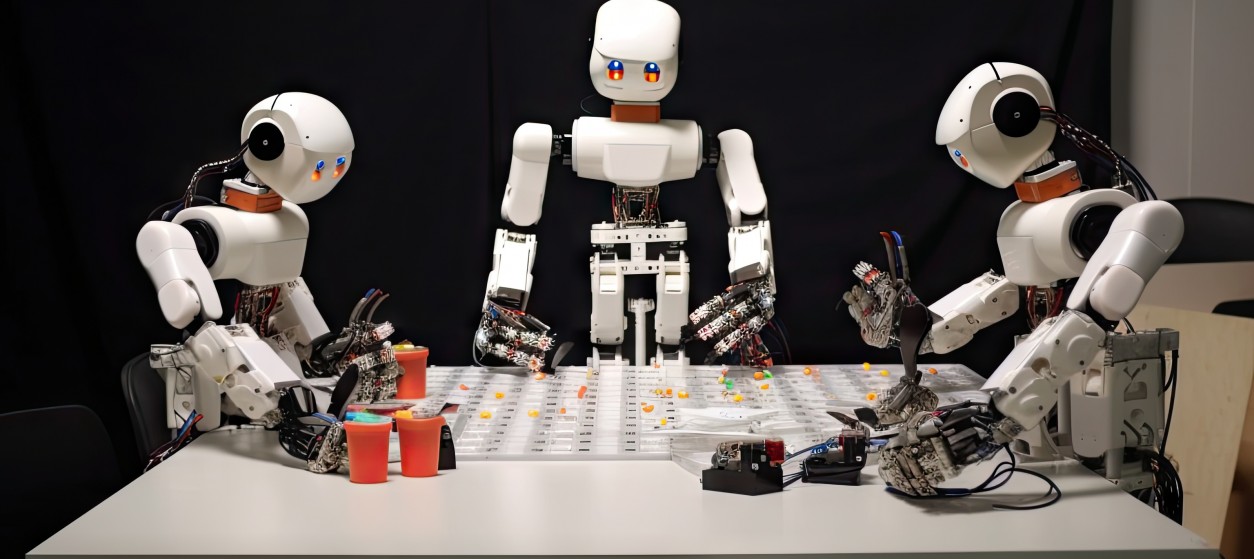

During recent years, industrial organizations are increasingly deploying digital technologies in order to automate and optimize their processes. In particular, in modern production shopfloors, technologies like Big Data, Artificial Intelligence and the Industrial Internet of Things, are combined with Cyber Physical Systems and Smart Objects like robots, drones and autonomous guided vehicles, in order to reduce laborious processes, to enable data-driven optimizations and to increase the efficiency of production systems. The deployment of these technologies signals a paradigm shift for the way processes are carried out, which reflects directly on the way workers engage in production tasks. In the scope of the emerging digitally enabled shopfloors, workers will no longer be carrying out labor intensive tasks, as these will be undertaken by robots and other forms of automation. Rather workers will be the supervisors of the new automated processes: they will oversee the operations of robots and other smart automation systems with a view to ensuring that they operate gracefully and in-line with production plans. As a result, while automation will inevitably replace several jobs, it will also create others that will revolve around the development, deployment and operation of digital technologies for industrial environments. This shift is commonly associated with the future of work in the scope of the fourth of the industrial revolution (Industry 4.0).

While automation systems increase the flexibility of production systems and processes, humans are still by far the most flexible resource in modern production plants. Nevertheless, for their successful engagement in production tasks workers will have to acquire the skills needed for understanding, operating and fully leveraging emerging production systems. This asks for significant investments in reskilling and upskilling processes that will provide workers with a proper set of digital skills as needed for their effective participation in the future of work. Likewise, industrial enterprises acknowledge the important of lifelong learning processes that will enable workers to keep up with the evolution of digital technologies and digitally enabled production systems.

The “Learning Factories” Concepts

To facilitate the reskilling and upskilling processes of workers in the manufacturing sector, a new learning and training concept has been introduced and is gradually implemented by industrial organizations: The “Learning Factory”. Learning factories are characterized by their ability to continuously plan and execute “on the job” training activities i.e. activities that are typically executed close to the production environment based on a hands-on approach. This is because manufacturers acknowledge that learning by doing is the best way for industry workers to acquaint themselves with the details and the operation of digitally enabled production systems.

Training processes in a learning factory are quite different from conventional classroom teaching and professional training activities. One of the main differences is that they take place in real-life production facilities and involve the actual equipment that workers should learn to use. In practice “hands on training” activities in the scope of a learning factories take place either in testbeds environments or in pilot production lines that are usually built close to the actual production lines. In some cases, they can also take place in the actual production line, especially when they involve knowledge transfer from other workers in real time i.e. during the occurrence of the production task.

Learning Systems and Technology Enablers

Learning factories are empowered by advanced training systems and technologies, which form the basis for modern Industry4.0 training and reskilling programs. Such systems include:

- Augmented Reality (AR) Systems. AR systems support the on-line training of workers in the real-life production environment. As a prominent example, AR systems can provide workers with cyber representations of how other more experienced workers perform a task (e.g., packing and picking in warehouse environments). AR enables the construction and display of such cyber-representations on the fly, as trainees try to perform the same task. In this way, trainees are provided with an on-line step by step guide on how to complete a process, which is displayed in their tablet or AR headset, without a need for consulting conventional paper manuals.

- Virtual Reality (VR) Systems. VR systems provide ergonomic and realistic representations of production tasks a means of transferring knowledge to trainees. VR systems provide video recorded cyber representations of the tasks, rather than displaying cyber representations that are created on the fly as in the AR case. Nevertheless, VR representations are in most cases realistic and help reducing the workers’ upskilling and reskilling learning curve.

- Interactive Learning Systems. Workers’ performance is a key element of the quality and efficiency of production processes. Therefore, it’s very important to help workers improve the way they perform tasks, including their speed and quality of work. In this direction interactive learning systems provide workers with feedback about how good they were at performing a task during training. This can greatly help workers improve themselves at quite short time. In practice, interactive learning systems sense the way workers perform a task (e.g., based on cameras or the quality of their outputs at the end of the task), as a means of providing timely, accurate and interactive feedback to them.

- Digital Simulations and Digital Twins. Digital simulation is one of the most prominent applications of the Industry 4.0 age. In addition to supporting what-if analysis for decision making, digital simulation systems can boost training processes, through enabling workers to consider alternative production actions and their impact in the outcomes of the production processes. To this end, workers can interact with digital twins of production systems and processes i.e. faithful representations of the physical systems in the IT world. Digital simulations and digital twins alleviate one of the main issues with physical processes, which is the fact that once an action is undertaken it cannot be undone. In the scope of a digital twin application trainees can experiment with alternative scenarios and evaluate their outcomes without experiencing the potentially adverse implications of their actions on the physical systems.

- Competence Frameworks. Competence frameworks complement and support the operation of the above listed systems through keeping track of the physical characteristics, emotional characteristics and skills of the workers. In particular, competence frameworks store and maintain the workers’ profiles and skillsets as they evolve based on the workers’ participation in the various production and training tasks. Therefore, they can provide information about the skills a worker misses in order to engage to a new production process or task. Likewise, competence frameworks can provide insights for building training applications (e.g., interactive applications or digital twins) that are tailored to the needs of specific workers.

Industry 4.0 opens up a whole new range of opportunities for industrial organizations. It creates however new obligations as well. One of these is to establish new approaches for the training and lifelong learning of their workforce. Fortunately, digital technologies like AR/VR can also support such new approaches. The result should be happier, more engaged and more productive workers, which are ready for the fourth industrial revolution and the future of work.